Surface Mount Technology: Trends and Innovations

Surface Mount Technology is at the heart of modern electronics production. SMT’s ability to integrate high-performance components on compact PCBs has revolutionized consumer electronics, automotive systems and telecommunications. Professionals and businesses must stay informed of the latest trends as the industry continues its growth and innovation. This article takes a look at the major developments that are shaping the SMT market today.

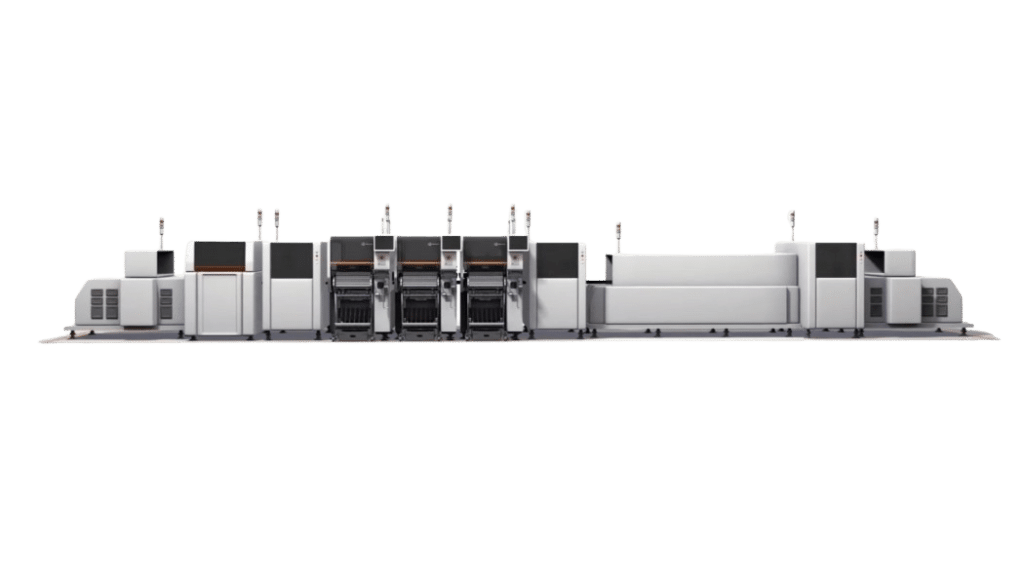

1. SMT Automation is Growing

Automation is a key component of SMT production, offering unmatched precision, speed, and efficiency. Robotic arms and pick and place machines have reduced human error while increasing throughput. Artificial intelligence (AI), machine learning, and other advances enable real-time adjustments and predictive maintenance to optimize performance.

Key Benefits:

- Cost reductions

- Production efficiency can be improved

- Improved product quality

2. Miniaturization of Components and Density

The demand for smaller components and a higher density of PCB components continues to increase as devices get smaller and more powerful. SMT manufacturers innovate to accommodate micro-sized packages such as 01005 while maintaining reliability and performance.

Challenges & Solutions:

- Pick-and-place technology is required to handle delicate components.

- Thermal management solutions will prevent PCBs from overheating when packed densely.

3. Lead-free and eco-friendly manufacturing

Global regulations such as RoHS (Restriction on Hazardous Substances), and increased consumer awareness of sustainability are driving the SMT industry to lead-free soldering. Manufacturers are adopting materials and techniques to minimize the environmental impact of their products without compromising on performance.

Adoption drivers:

- Conformity with international standards

- Corporate Social Responsibility (CSR) Initiatives

- Green products are preferred by consumers

4. Advanced Inspection Techniques

SMT manufacturing is not complete without quality control and inspection. Modern inspection systems detect defects accurately using 3D imaging, AI-driven analytics, and X-ray technologies. These systems guarantee that every PCB meets the high-tech application’s quality standards.

Popular Methods

- Automated Optical Inspection

- X-Ray Inspection

- Inline inspection systems

5. Industry 4.0 Integration

SMT manufacturing is being revolutionized by the integration of Industry 4.0. Smart factories with interconnected systems enable real-time monitoring and data-driven decisions, as well as seamless communication throughout the production line.

Features:

- IoT enabled equipment

- Real-time Data Analytics

- Predictive Maintenance Capabilities

6. Expanding Applications

In fields like 5G, wearable technology and electric vehicles (EVs), SMT is finding new uses. These sectors require high-reliability boards that can handle complex functions and extreme conditions.

Examples:

- High-frequency PCBs are required for 5G infrastructure

- Compact and durable boards designed for EVs

- Wearable PCBs with flexible PCBs

7. Workforce Development and Training

SMT technology is evolving, and so are the skills required by professionals. For the industry to remain competitive, training programs that focus on advanced machines, software tools and troubleshooting are necessary.

Areas of Focus:

- Understanding AI and IoT for SMT lines

- Learn advanced soldering techniques

- Troubleshooting high-tech machinery

The conclusion of the article is:

SMT’s future looks bright thanks to relentless innovation and a growing demand for high performance electronics. Manufacturers can deliver outstanding value to customers by embracing trends such as automation, miniaturization and Industry 4.0. BestSMT.com, a leader in SMT Solutions, is dedicated to helping companies navigate these advances and achieve unprecedented success in the electronics industry.